GOODALL INFRARED

SERVICES,INC Stator Core Testing Goodall Infrared Services,

Inc. is a consulting firm which has been in business since 1978 |

|

GOODALL INFRARED

SERVICES,INC Stator Core Testing Goodall Infrared Services,

Inc. is a consulting firm which has been in business since 1978 |

|

| BUILDING

ENVELOPES

|

|

ELECTRICAL SYSTEMS

|

|

| ELECTRONIC EQUIPMENT |

|

PULP

AND PAPER |

Paper Machine Reel |

| ROOFING |

|

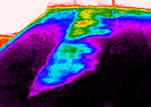

STEAM TURBINE-DRIVEN GENERATORS & HYDROELECTRIC

GENERATORS

|

|

There are a wide variety of services that we can offer to our

clients.

We would like to be of service to you.

If you have any questions about applications and services, please call

Goodall Infrared Services, Inc.

P.O Box 18677

Seattle, WA 98118

(206) 722-0544

1-888-848-1623

Page last updated

July 10, 2012

©2012 Goodall Infrared Services, Inc.

All Rights Reserved.